During the early days (1990’s) of Toyota Industrial Equipment (TIEM) in the US, we had to give consideration to many different processes as we developed the manufacturing operations. In my previous blog postings, I have tried to describe in (short form) how we went about many of these operational developments.

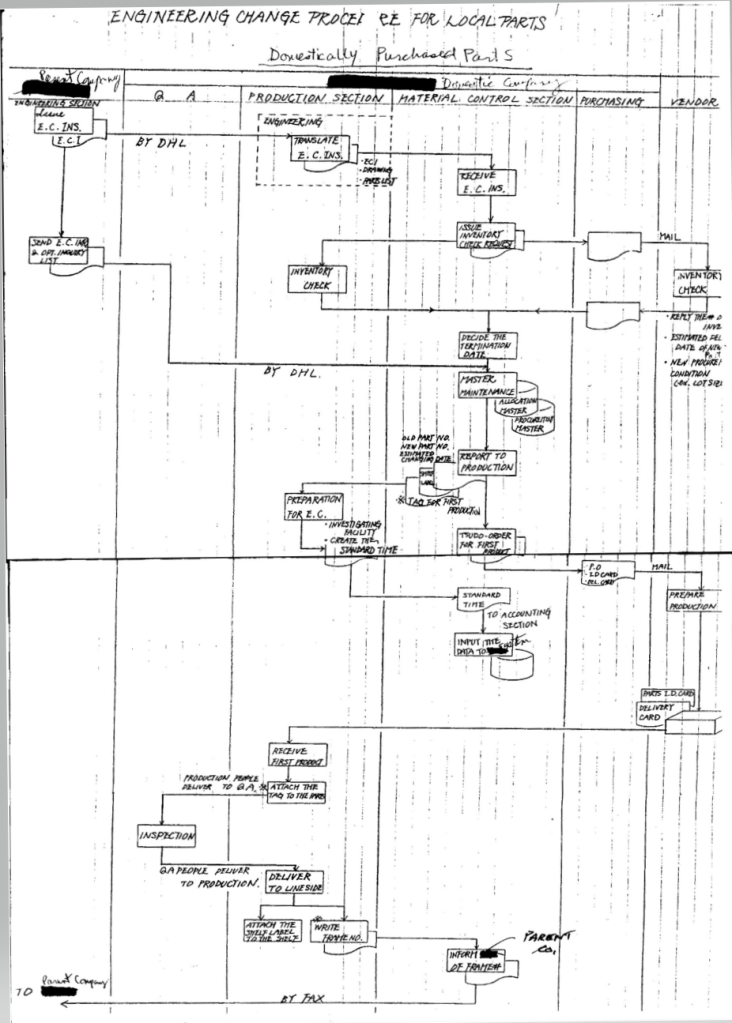

This article is another example of an important (critical) process – Engineering Change for Local (Domestically Purchased Parts). In the next two blogs (Volume 29 and 30) I will present Engineering Change Procedure for Import Parts (Interchangeable) and (Not Interchangeable). Frankly, the handwritten original examples are too big to display at the same time, so I split them into three volumes. Some of you might be more concerned with an engineering change procedure for domestic parts and some might be more concerned with imported parts. The three articles in Blog 28, 29, and 30 might be of help by showing how we managed engineering changes at TIEM.

In the example supplied here for Domestically Purchased Parts, it is noted that during those early days of the TIEM startup (1989+) the engineering was done by the TIEM parent company (TAL) and delivered to the TIEM operation (Domestic Company) in Columbus, Indiana. From that point, the process example tracks through the Quality Section, Production Section, Material Control Section, Purchasing Section, and on to the Vendor. In the mid-1990’s a substantial portion of product engineering was a joint effort by the local facility and the parent company in Japan. In previous blogs, I have explained how we encouraged customer, plant associates, and managers to work with Engineering to create improvements in quality, cost, convenience, service needs, etc.

In the example provided here, it is obvious that even in the 1990’s much of the process involved manual or semi-manual operational steps, as well as integrated into the ordering system. To control product quality and waste while introducing changes, it did involve significant manual intervention! Again, this example and those in the next two blog postings are intended only as examples from which you may be able to gain some ideas.